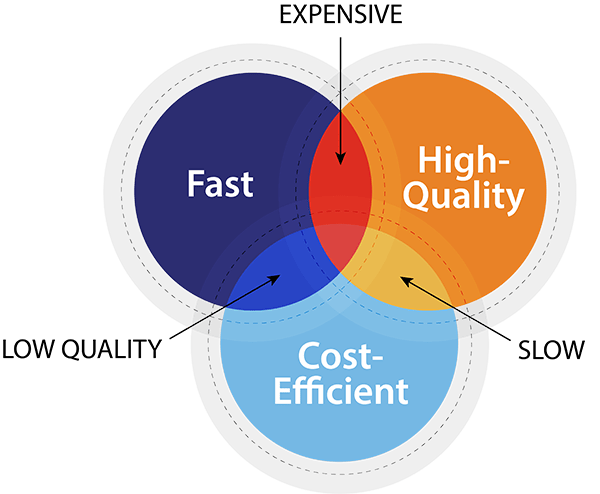

Fast, high-quality or cost-efficient: which two would you pick for your next print campaign?

You want all three, right?

There’s an old project management concept called the “iron triangle” that states you can only have two of the following, but never all three.

Cost-efficient + fast = lower quality work

Fast + high-quality = expensive

High-quality + cost-efficient = slow

When it comes to printing, however, two out of the three simply won’t do.

Even seemingly minor issues with print quality, such as a blurry image, can change the perception of your business from professional to amateur in the eyes of potential customers.

After all, print marketing materials are often the first impression prospects have of your business.

Working with a quality printing company ensures your business is presented in a professional, polished and memorable way.

When searching for a printing company, you’ll want to ensure they can provide fast, high-quality and cost-efficient solutions. Here’s why these three capabilities are so important for your business.

High-Quality Printing Solutions

Remember that your potential customers have been exposed to high-quality printed materials. Even if they’re not familiar with the print production process, they are able to tell the difference between high-quality and low-quality print jobs.

The difference is typically determined by the printing equipment and the experience of the printer.

There have been significant advances in printing technology and you’ll want to look for a printing company that continuously invests in modern printing equipment. Here are just a few of the reasons why modern printing technology is so important when it comes to quality.

Print Stability

Print stability, or the ability to precisely replicate an original image over and over again, can be difficult to achieve because the ink dries quickly from exposure to air. The result is poor-quality prints that lack the sharpness and colors of the original.

A common cause for poor print stability is due to ejection misalignment, which occurs when the ink has dried on the nozzle before the print run is complete.

Imagine trying to direct the spray of a garden hose when the nozzle is crusted with ice.

Even tiny crusts of ink on the nozzles can divert the inkjet stream just enough to make text fuzzy, while grays and colors are blended improperly because they’re not landing on the substrate precisely where they’ve been aimed.

State-of-the-art inkjet presses like the Konica Minolta KM-1 solve these issues with instant-drying LED UV ink. Picture-perfect prints are produced every time, on any substrate, and without the need for expensive coatings or special ink stocks. This expedites the production process and results in faster turn-around times. Even better, the KM-1’s LED UV ink keeps printed pieces vibrant and sharp after exposure to UV light, unlike offset prints which begin to fade within 30 days, so even outdoor signage won’t turn in the sun.

True Resolution

True resolution means that the printed image coming out of the printer retains the same high-quality resolution of the digital image put into it. Without true resolution, even the boldest of images can degrade from vibrant to mediocre.

To print in true resolution, you’ll want to ensure your printer has advanced digital printing technology. Jet Mail's uses the KM-1, for example, to print in high-dpi and low picoliters. This ensures images and messages retain their original sharpness, making every printed piece picture-perfect.

Cost Efficiencies That Boost Marketing ROI

You get what you pay for when it comes to printing and the cheapest printer isn’t always the best choice. However, a quality printing company should be able to provide custom solutions for your business that help improve the ROI of your print marketing strategy and simplify marketing operations–both of which result in cost efficiencies that can boost your bottom line.

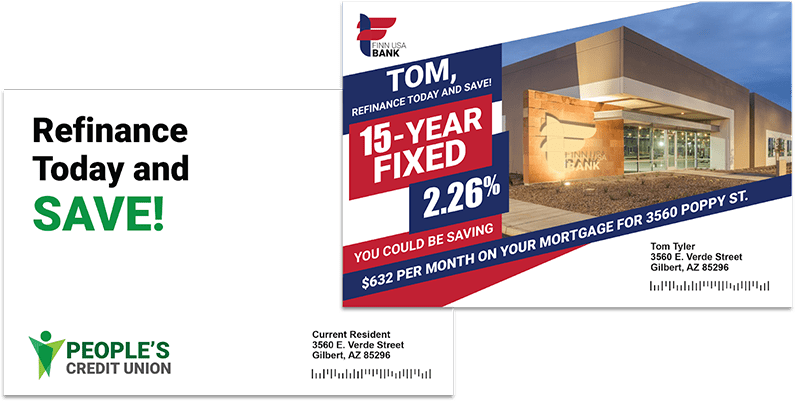

For example, you don’t have a one-size-fits-all audience, so your print marketing materials should be tailored to the unique needs of every customer. A printing company with variable data printing capabilities can amplify your print marketing strategy and boost ROI with the power of personalization.

Variable data printing allows for variables such as customer names, colors, images, headlines, and messages to be changed from one printed piece to the next, without interrupting the printing process. Since response rates for personalized pieces are 300% higher than non-personalized, you’ll see your marketing ROI soar without the high cost of one-size-fits-all “spray and pray” campaigns.

Additionally, should market trends, business goals or messaging suddenly shift, you can adjust your messaging in real-time to quickly meet the needs of your audience.

See the difference personalization makes in the graphic below. On the left is a non-personalized mailer printed in bulk with the same message for all recipients. On the right is a personalized mailer that leverages variable data printing and data from the company’s CRM to create a hyper-targeted and personalized message to the recipient.

In addition to personalization capabilities, you’ll want to look for a printing company that invests in technology beyond the production floor.

Take the Jet Mail Marketing Portal, for example. The portal allows marketing teams to manage all of their print, direct mail, fulfillment and shipping needs from an easy-to-use online platform. The portal saves both time and resources by:

- Simplifying the creation, production and distribution of marketing assets.

- Streamlining marketing operations.

- Printing on-demand vs. printing in bulk.

- Providing self-service access for users to order and personalize marketing materials.

- Centralizing and consolidating all marketing assets.

- Reducing manual processes, bottlenecks and delays.

Read the complete list of benefits that the marketing portal can provide here.

Technology like the KM-1 and Jet Mail Marketing Portal enable your business to deploy high-quality, personalized and effective campaigns. They also drastically expedite speed to market.

The Need for Speed

Getting your message in front of customers first and quickly reacting to new windows of opportunity can propel sales numbers skyward.

Fast print production and distribution times are critical for keeping your business top-of-mind and staying in front of competitors. You’ll want to look for a printing company that does more than just printing. By consolidating vendors and partnering with an all-in-one marketing fulfillment partner that specializes in speed to market, your print marketing campaigns will get into the hands of potential customers first.

Jet Mail’s in-house marketing fulfillment solutions include a state-of-the-art print shop, commercial mail house and on-site fulfillment center–all under one roof. This significantly expedites speed to market by:

- Reducing the number of vendors in your marketing supply chain.

- Sending print marketing materials directly to target audiences.

- Housing ready-to-ship materials in our 80,000 sq. ft. warehouse for same-day fulfillment from our in-house USPS facility.

Ready to experience the Jet Mail advantage?

Partner with Jet Mail for All Your Marketing Fulfillment Needs

Since 1993, the marketing fulfillment experts at Jet Mail have helped businesses deliver attention-grabbing print marketing campaigns that set their business apart from the crowd. Contact us today to learn more about our fast, high-quality and cost-efficient solutions for your business.

COMMENTS